HDPE Double wall corrugated pipes have a smooth – surfaced inner wall (colored yellow) surrounded by a profiled outer wall (colored black). The corrugated outer wall provides optimum strength under compressive loading form covering layers and traffic (High Ring Stiffness). The bright yellow color of the inner pipe also improves visibility in TV inspection, providing optimum, conditions for acceptance testing. Characteristics include:

HDPE Corrugated pipes are used in transporting liquids by gravity such as :

Manufactures according to DIN 16961 – 16566.

Ring thickness: SN8.

Pipes length: 12m.

| Inner Diameter | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Ø 150 | 150 | 181 | 187 | 197.4 | 2.3 | 1.1 | 1.2 | 2.5 | 67.3 | 19.08 |

| Ø 200 | 200 | 233 | 242 | 248 | 2.5 | 2.1 | 1.9 | 3 | 75 | 28 |

| Ø 250 | 250 | 291 | 303 | 310 | 3.0 | 2.3 | 2.1 | 4 | 85 | 33 |

| Ø 300 | 300 | 353 | 367 | 375 | 3.5 | 2.5 | 2.3 | 5 | 108 | 38.7 |

| Ø 400 | 400 | 460 | 476 | 485 | 4.5 | 2.8 | 2.6 | 6 | 142 | 51.4 |

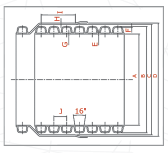

– Final Backfill: Decompressed area of soil (cross-sections are excluded).

– Initial Backfill: All solid materials are removed, decompressed area of soil.

– Bedding Layer: Decompressed area of sand.

– Ho: Distance between the ground to the top of the pipe.

– b: Width of the trench (mm).

– Y: Height of the bedding layer (mm).

– DN: Pipe outside diameter (mm).

– Ho has to be minimum 50 cm.