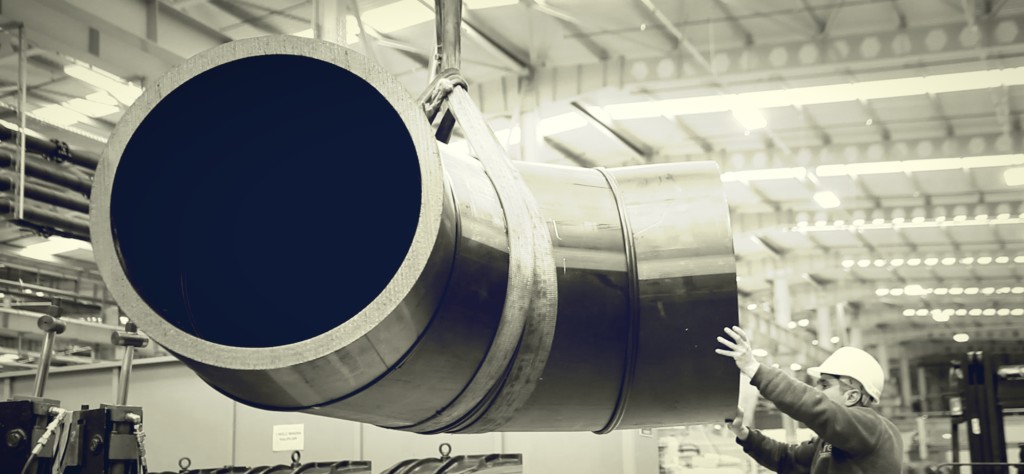

DELTA 1200 can weld various fittings including elbows, tees, wyes and stub ends. The 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe, while the fitting has to be locked in the 4th clamp. Short neck stub ends can be welded with the aid of a special tool (on request).

Product features:

– A machine body with a steel bearing frame

– Clamps and inserts in steel

– Self detaching device: helps removing the heating plate during welding procedure

– A heating plate, with separate thermometer for reading the working temperature, that can be extracted

– An electric milling cutter, with a safety microswitch and overload cutout, that can be extracted

– An electrohydraulic gearcase

– Digital electric connections box with the temperature controller

– A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

– Clamps’ inserts from Ø 710 to 1100 mm; Master 1000 mm; 28″ IPS ÷ 48″ IPS

– Tool for flange necks

– Electrical crane

– Machine body trolley

– Data-logging THE INSPECTOR

– Rollers

Technical features:

| Materials | HDPE/PP |

| Working range | Ø 710 ÷ 1200 mm 28 IPS ÷ 48″ IPS |

| Power supply | 400 V Three phase 50/60 Hz |

| Total absorbed power | 28200 W |

| Working temperature | 180° ÷ 280° C |

| Pressure working range | 0 ÷ 250 bar |

| Weight only body machines | 2500 Kg |

| Dimension | 2465x1870x1900 mm |