The Akafusion electrofusion couplers are delivered with centre stops. These stops can easily be removed with a knife or screwdriver (200, 250, 315), so that the coupler can be used as a slide-coupler. Before welding, cut pipe ends squarely with a pipe cutting tool, remove the oxide film with a scraper and mark the insertion depth. The couplers can easily be welded with our Akafusion control box and other suitable control boxes.

| Electrofusion Coupler Akafusion | |||||

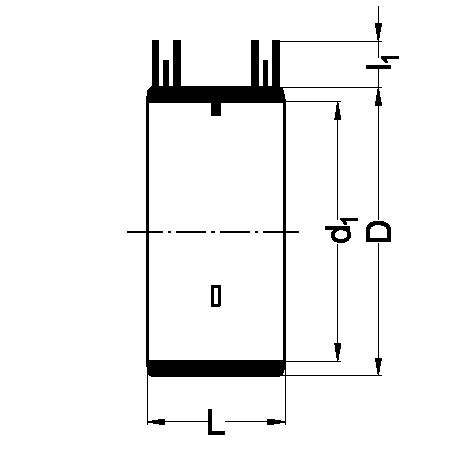

| Code | d1 | D | L | l1 | System |

| 41 04 95 | 40 | 52 | 54 | 22 | 5A/80s |

| 41 05 95 | 50 | 62 | 54 | 22 | 5A/80s |

| 41 56 95 | 56 | 68 | 54 | 22 | 5A/80s |

| 41 06 95 | 63 | 75 | 54 | 22 | 5A/80s |

| 41 07 95 | 75 | 87 | 54 | 22 | 5A/80s |

| 41 09 95 | 90 | 102 | 56 | 22 | 5A/80s |

| 41 11 95 | 110 | 123 | 60 | 16 | 5A/80s |

| 41 12 95 | 125 | 137 | 66 | 22 | 5A/80s |

| 41 16 95 | 160 | 172 | 66 | 22 | 5A/80s |

| 41 20 65 | 200 | 233 | 175 | 31 | 220V/420s |

| 41 25 65 | 250 | 283 | 175 | 31 | 220V/420s |

| 41 31 65 | 315 | 349 | 175 | 31 | 220V/420s |